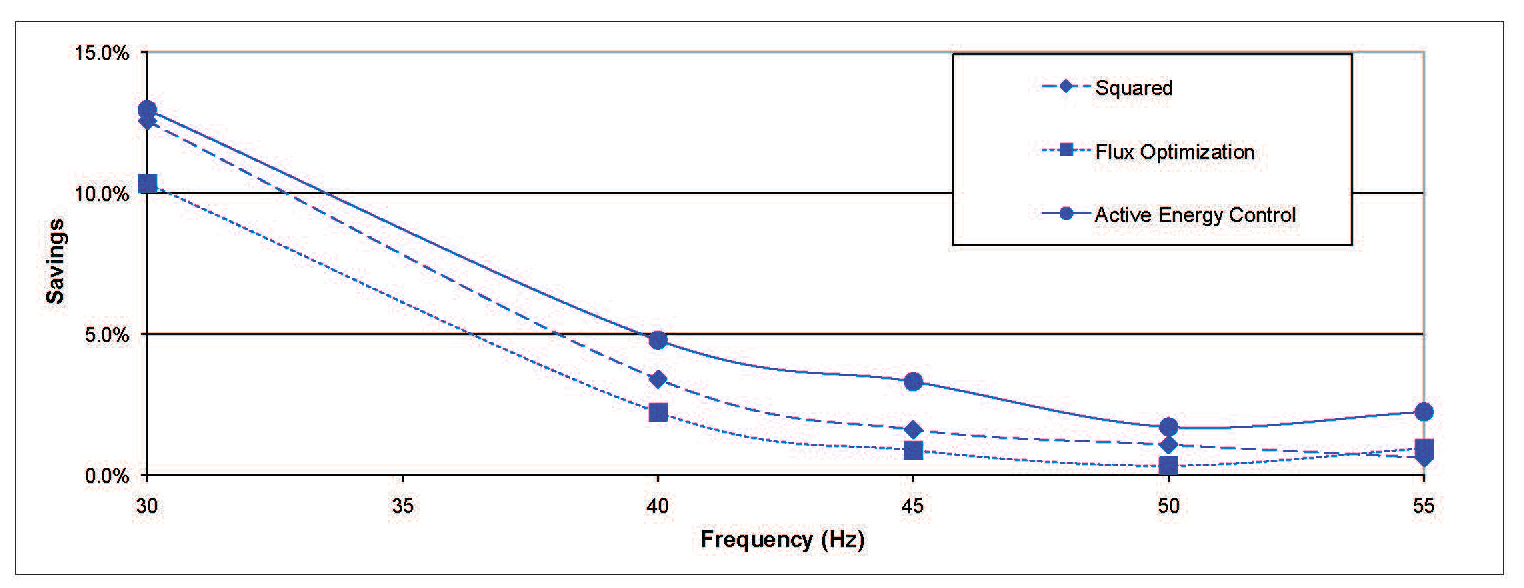

How to increase energy savings by up to 10% over a standard VFD

Active Energy Control® algorithm

Active Energy Control® is an energy optimizing algorithm that monitors the output requirements of the motor while reducing the input power requirements of the VFD in variable torque loads. By reducing the speed and running it below 60Hz, Active Energy Control® can optimize the input power required even more than a typical VFD.

How does it work?

The algorithm is enabled when the drive is commanded to start the motor either by following a reference frequency, or when a new one is entered by the user. For motor stability, the algorithm initially sets the drive output voltage at the same level as the voltage based on the linear V/Hz method for the same reference frequency. The voltage is reduced incrementally to optimize energy usage.

The algorithm monitors several real-time parameters of the motor to prevent instability conditions. When the motor enters the optimal zone of operation, the drive output voltage stays at the same level until there is a change triggered by commands to the drive (e.g., changes in reference frequency or real-time parameters). After the output voltage stabilizes, monitoring real-time parameters continues. Download the white paper to see the results from the energy savings tests conducted using a 50 hp motor.

For more information about Eaton’s drives solutions, visit Eaton.com/Drives.

To read more about this topic:

![]() Download the Solution!

Download the Solution!

Featured Product

H-Max® HVAC, VFD

Sign up for the Solutions! newsletter

Contact Eaton

For more information or to request a quote, fill out the form