Compact, connected and powerful automation.

Especially for small and medium-sized machines, automation solutions have to be compact, powerful, fast and flexible to use. Eaton's XC300 PLC with local and remote I/O levels more than meets these requirements. Together with the new XV300 HMI/PLC multi-touch panel, the XN300 I/O system and the updated GALILEO software, Eaton offers an innovative integrated automation platform. The XC300 also represents the latest in IT security and therefore meets all the network architecture requirements of the Industry 4.0 era. The connection to Eaton's Predictive Maintenance Portal is included.

Integrated technologies for more efficient, safer and more intelligent machines and systems.

Thanks to its enhanced functionality, the new generation of Eaton's digital NZM circuit breaker with up to 1,600 A will increase the reliability of your machines and systems. It offers improved features for the protection of personnel and will help you optimize your energy consumption. The extended communications capability makes it the perfect fit for the changing production environments of Industry 4.0.

Data transparency is of ever greater importance for end users. Eaton's intelligent components offer a wide range of possibilities for the collection and transmission of machine data. Together with our partner T-Systems we make IoT happen, with cloud services that are both secure and hassle-free. For example through our Predictive Maintenance Portal.

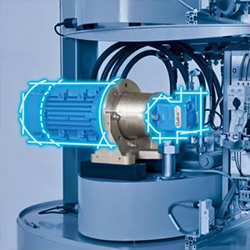

As a one-stop-shop for electrical and hydraulic technology, Eaton is able to offer uniquely synergistic solutions. One such example are our simple plug-in solutions for connecting hydraulic valves to SmartWire-DT. At the same time, we also help you generate the data needed for Industry 4.0 solutions. This year, we are showcasing our electro-hydraulic solutions at a single stand for the first time.

Cost effectiveness in drive technology is not merely a question of energy efficiency. For machine builders and system integrators, efficiency is a primary concern, from the planning phase all the way to commissioning. It thus makes a big difference whether features such as multi-pump controls are standard, as is the case with the DG1, or still have to be purchased later on. Discover the efficiency potential of our entire PowerXL™ range, including the new DB1 series, at the Hanover Fair.

Given the high degree of complexity and the constant changes, exports to North America pose a great challenge for many machine builders. For example, the new NEC 2017 rules on short-circuit current rating (SCCR) affect not only the SCCR requirements themselves, but also the labeling and documentation of devices.

Our electro-hydraulic precision machine demonstrates how easy it is to achieve greater degrees of energy efficiency, performance capacity and IoT integration - with integrated solutions that will create added value for your customers. The data generated by our intelligent system components is transferred directly into the cloud. Based on the subsequent data analysis, you will then be able to improve production capacity, product quality and uptime while reducing maintenance needs.